There are many types of valves available across a wide range of industries, with each having a specific function that makes it suitable for some applications but not others. To choose the most appropriate valve, you need to understand the applications.

Valve applications

The range of industries that use valves in one form or another is a broad one, which is reflected in the size and value of the international valve market.

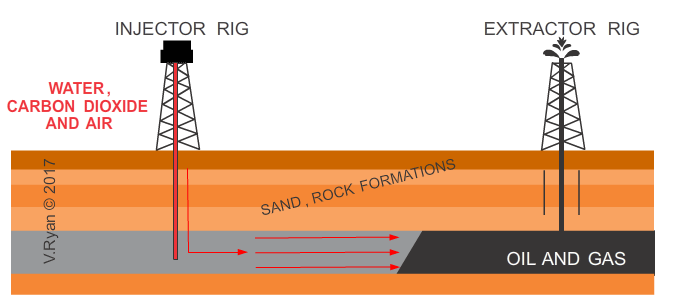

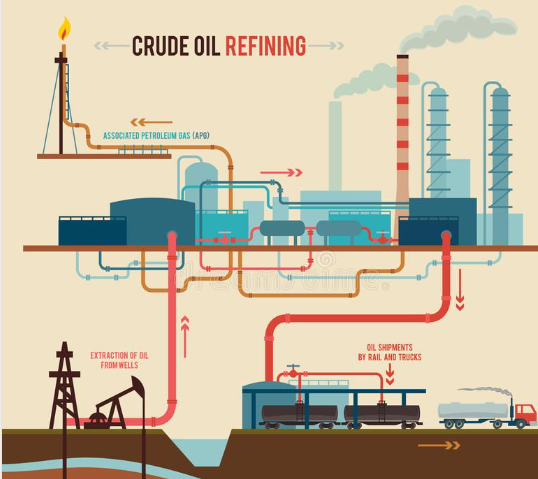

The process of extracting and refining oil or gas generally requires extensive use of pipes. Power plants have pipes to transport gas, water and steam, often at very high pressures. Another industry that relies on the flow of water through pipes is sewage, but this can often be done at lower pressures and temperatures. Mining also uses pipes, but the substances often consist of larger particles that are high in hardness and viscosity and may have corrosive acidic or alkaline properties.

Common types of valve

Valves exist to regulate the flow of different substances in both liquid and gas form, as seen from the selection at https://orseal.com/. Gate valves, which have a wedge shape and can only be set to on/off rather than to moderate flow, are the most common valves used when refining crude oil.

If you want to adjust flow rates, globe valves are a good option. For wastewater transportation in sewage systems, the preferred choice is check valves that prevent the flow from reversing direction. Butterfly valves can be used with most substances, including water, air, steam, and even slurry. A particularly modern option is the ball valve.

These are some of the most common types and applications for industrial valves. Choosing the most appropriate one will ensure safer and more effective performance.