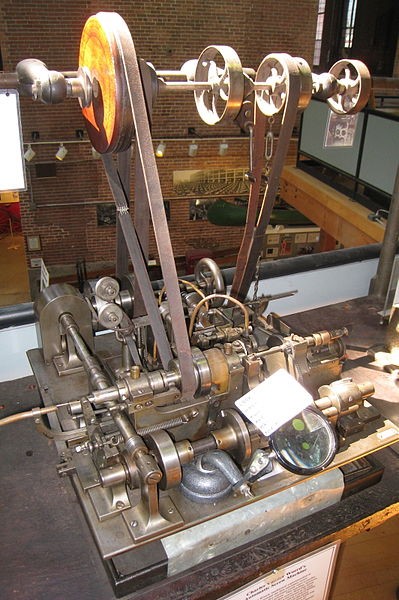

If you want to improve product quality while reducing costs, automation makes sense. By automating processes including material handling and assembly, you can reduce manufacturing lead time and accomplish some processes that can only be fully controlled by computer systems. Automated systems can free workers from the boredom of repetitive tasks while improving quality and productivity.

Technological advances have changed the nature of manufacturing but automation can still seem a daunting process. Ultimately, there can be a higher cost for not automating your manufacturing processes when you look at the benefits.

1. Increasing productivity

Machines don’t need time to think and can perform certain operations far more efficiently than manual labour. Automating processes increases the total rate of production, delivering greater output per hour and can reduce the number of boring, tiring and repetitive operations that employees need to perform.

2. Improving safety

Dangerous work is made safer when employees take a supervisory role. Since the introduction of the Health and Safety at Work Act, workplace safety has been a priority for all businesses and automation helps cut hours lost through accident and injury.

3. Reducing costs

Investing in automation can reduce labour costs by replacing manual operations and freeing employees for more skilful tasks. This collaborative automation will be a key driver of the Industrial Revolution 4.0.

4. Maintaining quality

The repeatability of automated tasks means that a machine can get a task done more precisely than a human. For example, when using nickel composites for coating, automation ensures a precise current, time and temperature for the optimum bond. The reduction of defects and greater uniformity of products is a critical benefit of automation which can ensure that every product conforms to the same quality specification.

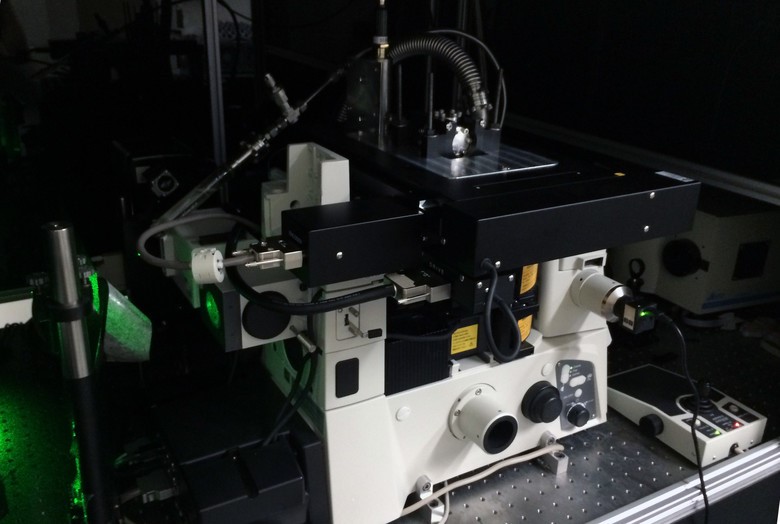

5. Accomplish impossible tasks

Certain manufacturing processes just can’t be achieved without the use of automation. Nickel composites, for example, cannot be applied by hand but require a highly controlled automated process to ensure optimum results. This applies to processes including miniaturisation, integrated circuit fabrication and prototyping based on complex CAD graphics.

It’s estimated that smart factories will add $500 billion to the global economy by 2020. Better company image, higher quality products, a happier workforce and improved sales are all benefits of the move towards greater automation. Add in reduced lead times and ask yourself whether your business can afford not to automate?